Something about GOB LED display that may interests you.

GOB is the abbreviation of Gluing on board.

It is a new technology of led display packaging technology to solve the problem of LED lamp protection.

This material not only has ultra-high transparency to ensure the well visibility but also has superior thermal conductivity to encapsulate the substrate and it’s LED module panel to form effective protection.

The GOB led display can be adapted to any harsh environment than SMD led display with smaller pixel pitch to achieve the true moisture, water, dust, impact and UV resistance.

GOB led display which the characterized by simpler maintenance, lower maintenance cost, larger viewing angle, and 180-degree horizontal viewing angle and vertical viewing angle.

Compared with COB led display, GOB led module display can be good for both small and big pixel led screen, more widely used application, perhaps more crucial is the better cost than COB led display.

Yonwaytech led display GOB series also can brings with advantages as below.

(1)High protection ability

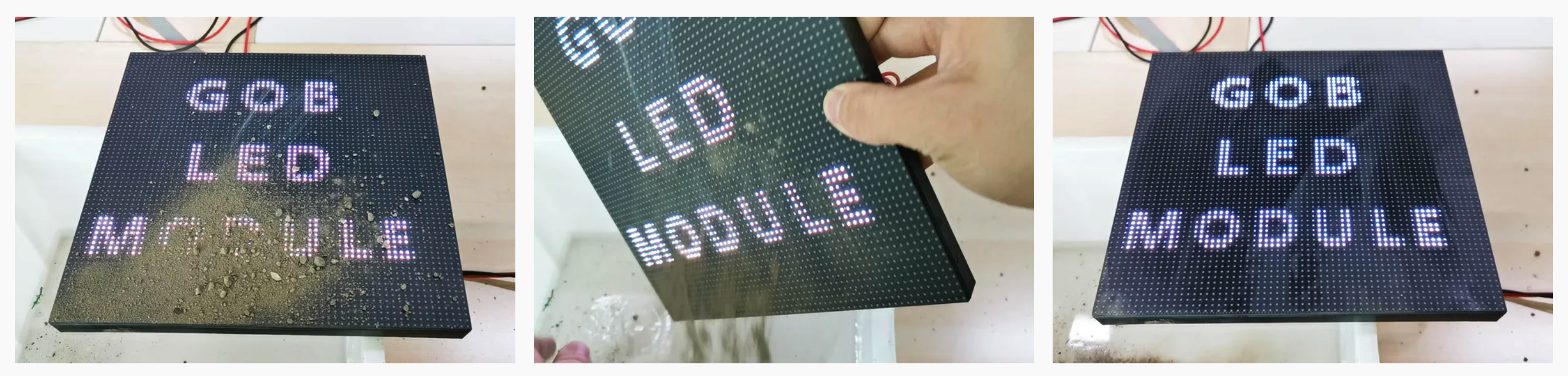

The most outstanding feature of GOB LED is the high protection ability which can prevent the displays from water, humidity, UV, collision, and other risks effectively.

This feature can avoid large-scale dead pixels and broken pixels.

(2)Advantages over COB LED

Compared with COB LED, it is easier to maintain and has lower costs of maintenance.

Besides, the viewing angle is wider and can be up to 160 degrees both vertically and horizontally.

Moreover, it can solve the bad surface evenness, inconsistency of color, high reject ratio of COB LED display.

(3) Suitable for narrow pixel pitch LED display and flexible soft LED display.

This type of GOB LEDs are applied mostly on small pixel pitch LED screen with pixel pitch P2.0mm or smaller, and also suitable for LED display screen with higher pixel pitch.

Besides, it is also compatible with flexible PCB board and can meet the high requirements for high flexibility and seamless display.

(5)Higher contrast

Due to the matt surface, the color contrast is improved so as to increase the play effect and wider viewing angle.

(6)Friendly to naked eyes for creative 3D VR led display

It will not emit UV and IR, and also radiation, which is safe to people’s naked eyes.

Besides, it can protect people from the “blue light hazard”, as blue light has a short wavelength and high frequency, which may lead to damages to people’s eyesight if watch it in a long time.

Moreover, the materials it uses from LED to FPC are all environment-friendly and recyclable that will not cause pollution.

It is also suitable for flexible LED displays and can own excellent flexibility for accurate 3D LED screen installation based on the structure of the building.

There are also some strict requirements from

Yonwaytech led display production process of GOB LED display:

(1) Materials

The most basic elements is high-quality materials like LED chips, ultra-high refresh drive IC, excellent heat dissipation good quality PCB board, for instance, Yonwaytech LED Display configured their p1.25 indoor led module with 2.0mm 6 layers copper PCB to ensure a good quality GOB led module.

Also the packaging materials must have features like strong adhesion, high stretching resistance, adequate hardness, high transparency, thermal endurance, good abrasion performance and so on. And it should be anti-static and can resist high pressure to avoid the shortening of service life because of crash from outside and static.

(2) Packaging process

The transparent glue should be padded accurately to cover the surface of lamp lights and also fill in the gaps fully.

It must adhere the PCB board tightly, and there should not be any bubble, air hole, white point, and gap which is not filled with the material totally.

Yonwaytech led display always focus on high quality led module display product, we select good quality led display components, also skilled production progress in the GOB package.

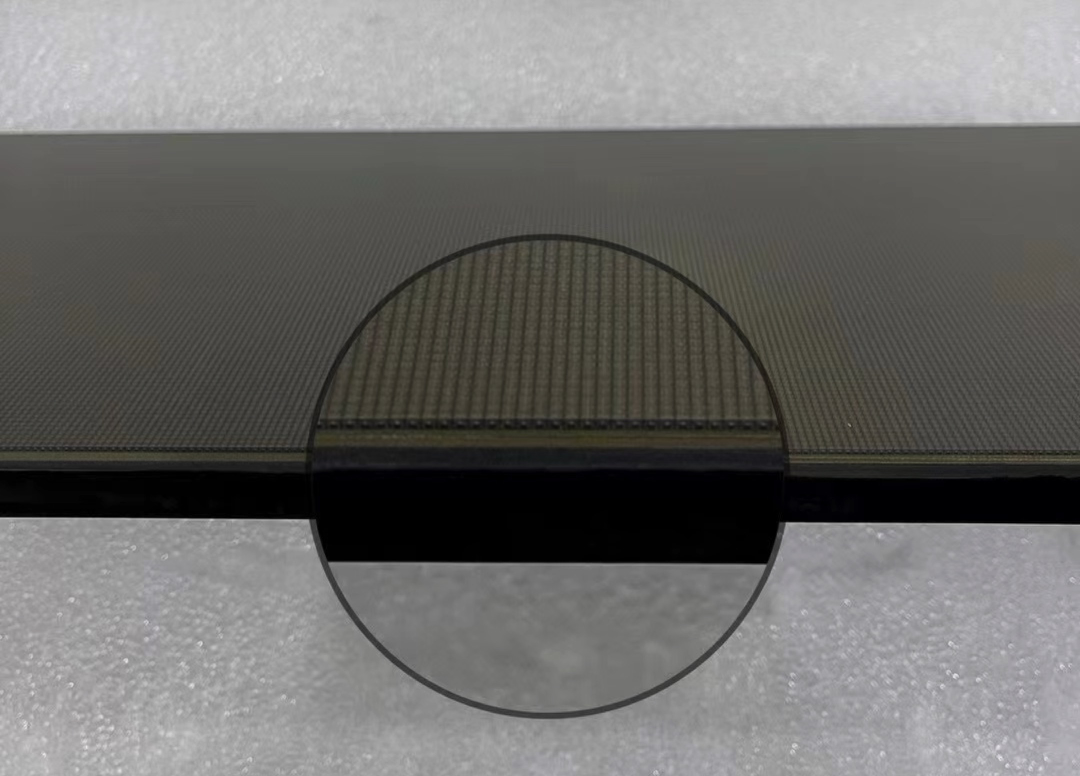

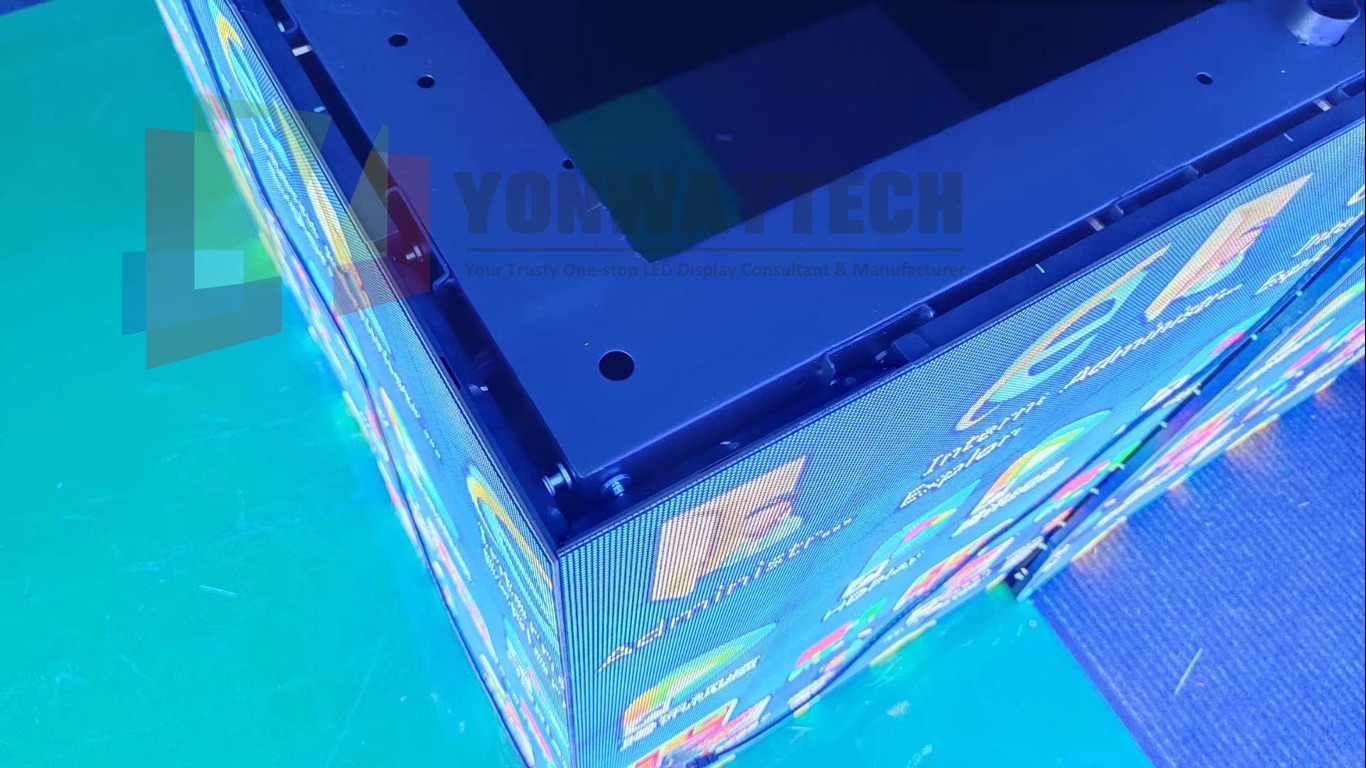

(3) Uniform thickness

After the GOB packaging, the thickness of the transparent layer must be uniform.

With the development of GOB technology, now the tolerance of this layer can be almost neglected.

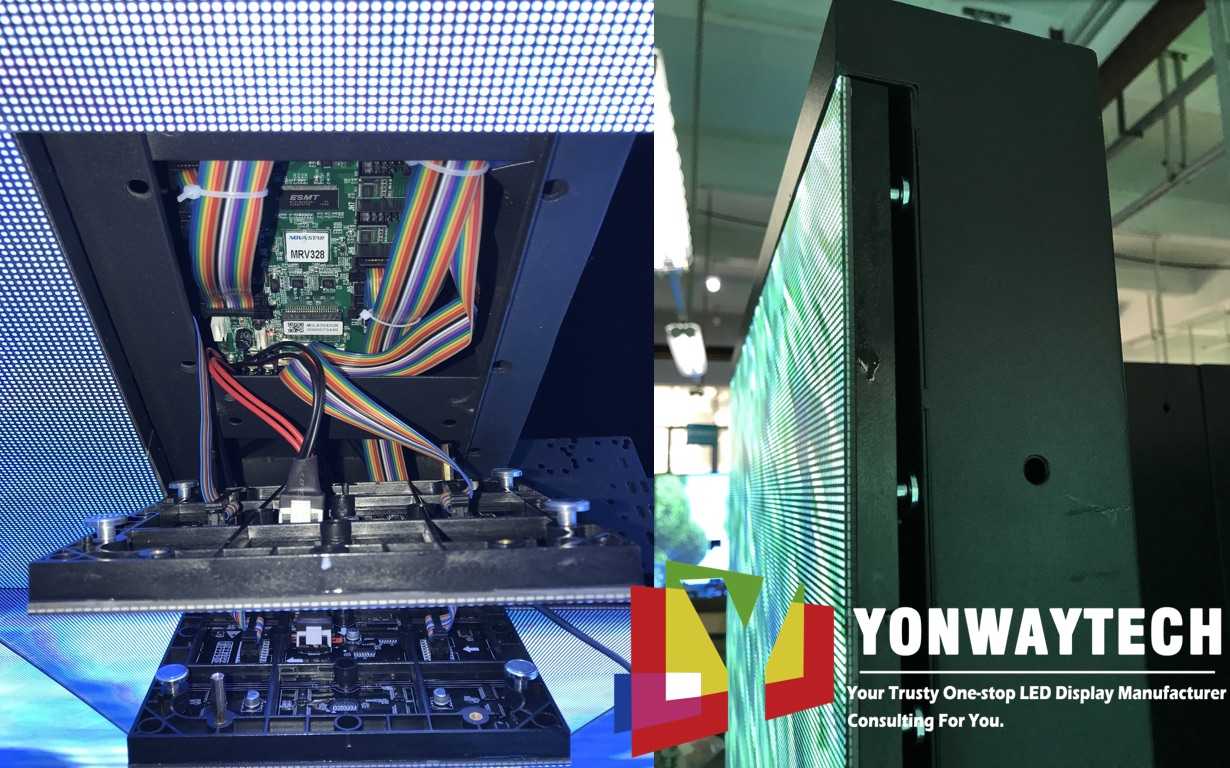

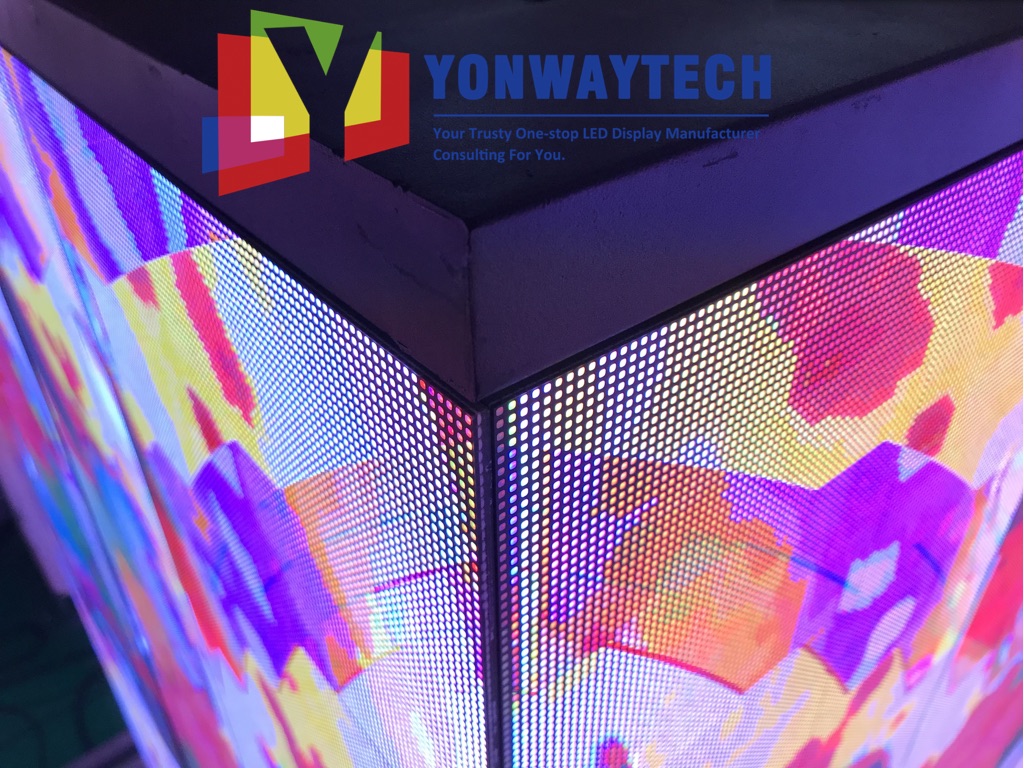

Yonwaytech LED Display Outdoor GOB pillar led display.

(4) Surface evenness

The surface evenness of Yonwaytech led module display should be perfect without irregularity like small pot hole.

(5) Modular testing before and after gluing

After the SMD led module product assembled, aging for 72 hours before GOB filling, the lamp is tested well.

It is worth to be highlighted that Yonwaytech led display make the GOB module with another 24 hours to confirm the product quality again before assembly in led display.

(6) Maintenance

The GOB LED screen should be easy to maintain, and the glue can be easy to move under special conditions to repair and maintain the rest part.

As the outstanding protective layer covering the led module surface, it can deal with the problem that unnecessary damages caused by people such as falling down of the lamp beads especially for LED lamps placed on the corner,

GOB LED Display can be widely used for outdoor applications and indoor applications where people can access the LED screen easily such as elevator, fitness room, shopping mall, subway, auditorium, meeting/conference room, live show, event, studio, concert, etc.